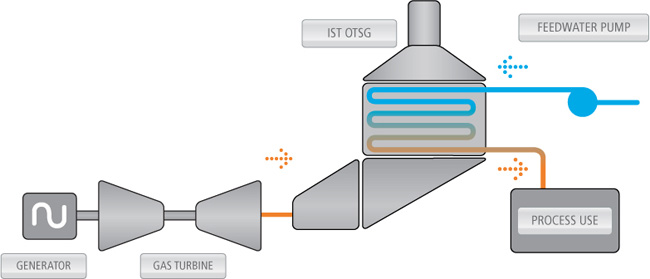

Cogen

Steam generation for Cogen plants involves significantly less maintenance and wasted energy with IST’s OSTG technology. Initial installation time and associated costs are also reduced because the IST unit is factory built and shipped virtually ready to connect. Each pressure part module is completely hydrostatically tested prior to shipment, often 100% of the pressure parts are also welded and complete in our factory prior to transporting to site.

Alloy Steel allows generator to run dry

But one of the most significant benefits is one you may not have imagined; the alloy steel used in IST’s tube bundles allows the generator to run dry! No time consuming shut-downs or bypassed exhaust energy common to drum-type steam generators. IST sales and proposal representatives will choose the best alloy tube material depending on your applications requirements.

Flexible operation

Best of all for Cogen plants is the flexibility and ease in cycling from 0% to 100% steam capacity with OTSGs. The OTSG lacks a fixed economizer, evaporator and superheater section. The OTSG tube bundle is a continuous flow tube bundle which produces superheated steam in one pass. The steam production is maintained by a single point of control, the feedwater control valve. The OTSG design Simply Generates More Profit!

Typical cogeneration applications include pulp and paper plants, chemical production and district heating programs where sudden changes in steam demand and temperature are necessary. OTSG’s low thermal inertia and unique drumless design makes this possible.

IST

IST