About OTSG

Once Through Heat Recovery Steam Generators (OTSGs) are the most significant advancement in steam generation in over a century.

Until the 1980s, conventional drum boilers were used to produce steam.

At about this time, the US Navy investigated the use of combined gas turbine and steam turbine plants for additional ship propulsion power. The US company Solar Turbines made significant progress in refining the OTSG concept for both ship-board and land based use.

The formation of Innovative Steam Technologies (IST) coincided with IST’s acquisition of OTSG technology from Solar Turbines in 1992. IST put the technology to work in Heat Recovery Steam Generator (HRSG) applications operating off gas turbines.

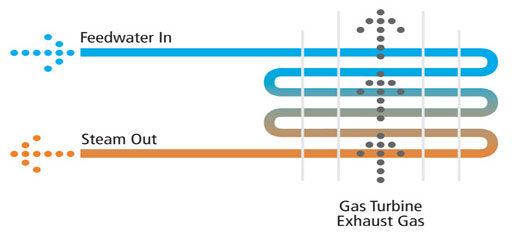

Simply described, an OTSG consists of:

- an enclosed structure with an inlet at the bottom end that accepts heated air (usually exhausted at high velocity from a gas turbine) and an outlet at the top of the structure that allows the air to escape;

- inside this enclosed structure is an uninterrupted bank of high quality steel tubes. Feedwater is fed into the top of the tube bank and is heated by the turbine’s exhaust gas to create steam at the outlet end of the tube bank.

OTSGs unique features benefit users in four significant ways:

- Faster installation – OTSG units are manufactured in modules so they install quickly (typically 48 weeks versus 60 weeks for conventional drum type generators)

- Run-dry capability – no need to shut down gas turbines- because of the alloy steel used in IST’s OTSG tube bundles, they can continue to operate when steam is not required

- Drumless steam generation – there are no blow-down systems, steam drum level worries or boil out and chemical cleaning requirements with OTSGs. OTSGs have significantly fewer components and approximentally 50 less I/O points- for reduced maintenance costs.

- Flexible operation – run dry capability and the drumless simplicity of OTSG installations means lower maintenance and greater flexibility- including easy and fast cycling from 0% to 100% steam capacity.

Today, IST OTSGs are used world-wide in steam generation applications, providing unique benefits for gas turbine Power Generation and Enhanced Oil Recovery operations:

IST

IST